卫生级离心泵和卫生级自吸泵(20-05-06)

三级乳化泵的优势就什么?(19-05-08)

卫生级离心泵的相关知识(19-05-08)

卫生级离心泵运行及6大故障处理(19-05-08)

不锈钢多级离心泵叶轮维修(19-05-08)

高剪切乳化机的特色及运用(19-05-08)

产 品 简 介

Product introduction

高剪切乳化机是本企业吸取消化国外新型技术和工艺研制开发生产的新产品,各项指标达到国内新型水平。产品质量完全符合GMP技术要求IS09001认证产品,特别适用于再食品、饮料、化工、生化、石化,颜料、染料、涂料、制药等领域必不可少的混合液的乳化均质机械设备,总体结构简单、体积小、重量轻、易操作、噪音低及运转平稳诸优点,其具有大特点在生产工艺流程中不采用研磨介质,集高速剪切、分散、乳均、均质、混合、破碎,输送一体化功能。

High shearing dispersion emulsifier is our new product with advanced technology from home and abroad, whose indicators can achieve world level. It can satisfy GMP standard and ISO9001, can especially be used in food, beverage, chemistry, biochemistry, petrochemical, pigment, dye, dope and pharmacy fields which need emulsification and homogenization. The product is simply structured with small volume and weight. It generates very little noise and works efficiently, gently and smoothly.

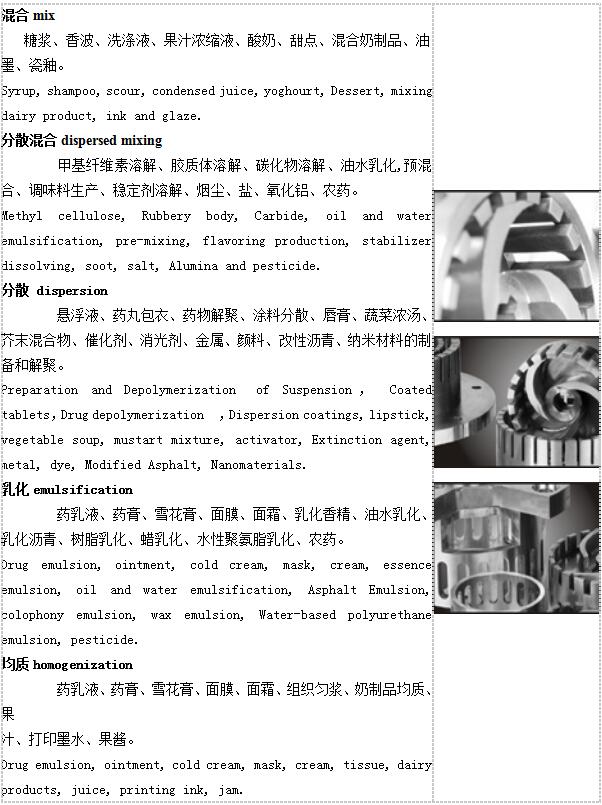

应用范围

Applied range

食品工业:辣椒酱、芝麻、果茶、冰淇淋、奶油、果酱、果汁、大豆、豆酱、豆沙、花生奶、蛋白奶、豆奶、乳制品,麦乳精、香精、调味品、各种食品饮料等。

Food industry: chili sauce, gingili, fruit tea, ice cream, butter, jam, soy, miso, red bean paste, peanut milk, protein milk, soymilk, dairy product, malted milk, essence, condiment and all kinds of food and beverage etc.

化学工业:油漆、颜料、染料、涂料、润滑油、合成脂、润滑脂、柴油、石油催化剂、乳化沥青、改性沥青、石腊、胶粘剂、洗涤剂、塑料、炸药、玻璃钢、合成革、树脂、皮革及乳化炸药等。

Chemistry industry: oil paint, pigment, dye, dope, lube, diesel oil, Oil catalyst, asphalt Emulsion, modified asphalt, paraffin, Adhesive, scour, plastic, detonator, FRP, Synthetic Leather, colophony, leather and Emulsion explosives.

日用化工:牙膏、洗涤剂、面霜、唇膏、洗面奶、洗发精、鞋油、化妆品、沐浴精、肥皂、混凝剂、香料及香脂等。

Daily Chemical Industry: toothpaste, scour, cream, lipstick, facial, shampoo, shoeshine, cosmetic, shower concentrate, soap, Coagulant and flavor

医药工业:各型糖浆、营养液、中成药、膏状药剂、生物制剂、鱼肝油、花粉、蜂皇浆、疫苗、各种药膏、各种口服液、杀菌剂、针剂、抗菌素、微胶囊及静滴液等。

Medical industry: sirup, Nutrient Solution, Chinese medicines, Pharmacy paste, Biological agents, Cod liver oil, pollen, Placenta, bacterin, ointment, liquid, Fungicides, injection, Antibiotics, Micro encapsulation and Intravenous fluid.

建筑工业:各种涂料。包括内外墙涂料、防腐防水涂料、冷瓷涂料、多彩涂料、陶瓷釉料、纳米涂料及喷涂等。

Construction industry: all kinds of dope including Internal and external wall dope, antisepsis and waterproof dope, Cold porcelain dope, colorful dope, Ceramic Glaze, nano dope and spraying.

造纸工业:纸浆、胶黏剂、松香乳化、造纸助剂、树脂乳化等。

Paper making industry: paper pulp, Adhesive, Rosin Emulsion, Paper Additives and Resin Emulsion.

农药工业:杀菌剂、种衣剂、除草剂、农药乳油、化肥、生化农药、生物农药等

Pesticide industry: antiseptic, herbicide, Pesticide EC, Fertilizer, biochemical pesticide and biological pesticide.

其它工业:纺织工业、煤炭浮选剂、稀土、纳米材料分散解聚、反应萃取及军工等领域。

Other industries: spin industry, Coal flotation agent, rare earth, nanomaterial Scattered depolymerization, reaction, extraction and war industry.

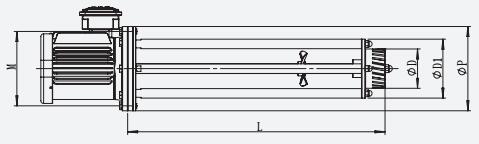

WRL系列高剪切分散乳化机图样: PIC

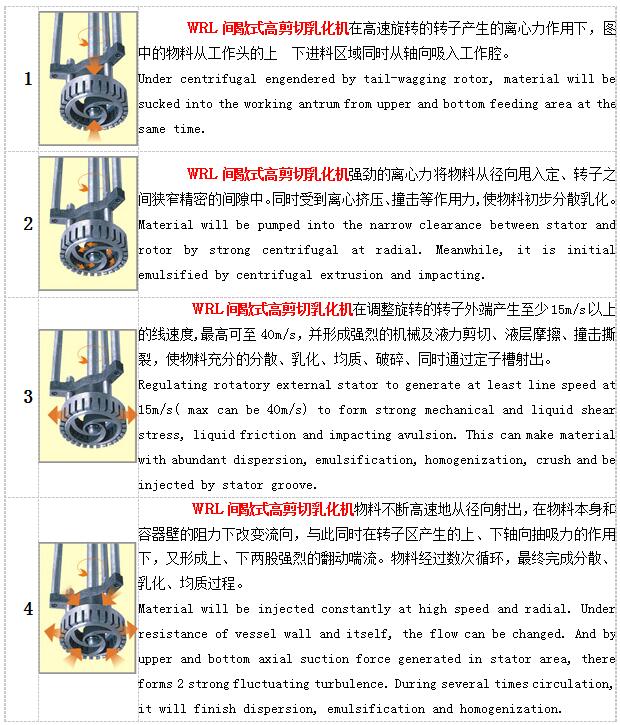

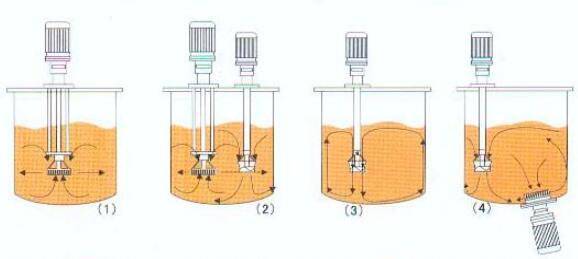

WRL间歇式高剪切工作过程步骤:Working process steps

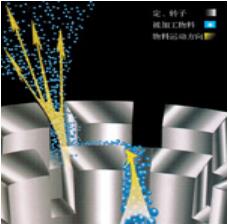

WRL系列高剪切分散乳化机工作原理:Working principle

WRL间歇式(立式)高剪切分散乳化机是效率高、快速、均匀地将一个相或多个相分布到另一个连续相中,而在通常情况下各个相是互相不溶的。由于转子高速旋转所产生的高切线速度和高频机械效应带来的强劲动能,从而使不相溶的固相、液相、气相在相应成熟工艺和适量添加剂的共同作用下,瞬间均匀精细地分散乳化,经过高频的循环往复,终得到稳定的品质高产品。

It is highly efficient, fast and equably to distribute 1 phase or several phases to a continuous one. But normally they are not dissolvable with each other. Under use of techniques and proper additives, high tangent speed and strong kinetic energy generated by high speed rotary rotor and mechanical effects can lead to instant, equally, subtly and dispersed emulsification of solid phase, liquid phase and gas phase. After high frequency reciprocating circulation you can get high quality steady product.

WRL高剪切分散乳化机处理工艺: Process

WRL系列高剪切乳化机性能表:Performance chart

| Model 型号 |

Power 功率KW |

Rotary speed转速rpm | Handling capacity 处理量L |

| WRL90 | 1.5 | 2800-290 | 5~5 |

| WRL100 | 2.2 | 50~10 | |

| WRL120 | 4 | 100~30 | |

| WRL140 | 7.5 | 200~80 | |

| WRL160 | 11 | 300~100 | |

| WRL180 | 18.5 | 500~150 | |

| WRL200 | 22 | 1400-150 | 800~200 |

| WRL220 | 3 | 1000~300 | |

| WRL240 | 37 | 1500~500 |

订货须知: order notice

*表中流量范围是指介质为"水"时测定的数据。

Flow range data in chart is based on material(water)

*如介质粘度或稠度较高,建议与管线式高剪切均质乳化机配合使用。

If material viscosity is high, we suggest to with use of homogenizing machine.

*如有高温、高压易燃、易爆、腐蚀性等工况,必须明确提供相关准确的参数,以便正确选型定制。

If there are high temperature, high pressure and flammability, explosive and Corrosion, please afford exact parameters, so as to choose the right model.

*产品在不影响基本结构及性能的改进时,恕不另行通知。(2008版本)

WRL系列间歇式生产工艺:Intermission processing techniques

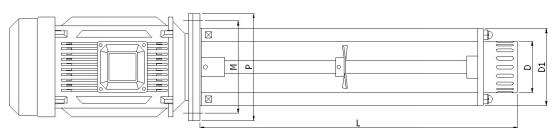

WRL系列高剪切乳化机外形尺寸:Dimension

| 型号 | D | D1 | P | L | M |

| WRL90 | 80 | 140 | 200 | 355 | 165 |

| WRL100 | 88 | 145 | 200 | 650 | 165 |

| WRL120 | 120 | 180 | 250 | 750 | 215 |

| WRL140 | 140 | 210 | 300 | 900 | 265 |

| WRL160 | 160 | 230 | 350 | 1050 | 300 |

| WRL180 | 180 | 260 | 350 | 1200 | 300 |

| WRL200 | 200 | 270 | 350 | 1200 | 300 |

| WRL220 | 240 | 320 | 400 | 1355 | 350 |

| WRL240 | 260 | 340 | 400 | 1395 | 350 |